德阳tangibleCylinder batcherConcrete is actually "concrete."。Concrete, referred to as "concrete (tong)" : refers to the aggregate cemented into a whole by the cementing material engineering composite material collectively。Generally speaking, the term concrete refers to the use of cement as a cementing material, sand, stone as aggregate;With water (with or without admixtures and admixtures) according to a certain proportion, by mixing, forming, curing and cement concrete, also known as ordinary concrete, it is widely used in civil engineering。It is made of cementing material, aggregate and water according to a certain proportion of preparation, by stirring vibration molding, under certain conditions of maintenance of artificial stone。tangibleCylinder batcherConcrete is rich in raw materials,Low price,The production process is simple,So the use of more and more;At the same time, concrete also has high compressive strength,Good durability,Wide range of strength grades,Make it a very wide range of use,Not only used in various civil engineering,The shipbuilding industry,Machinery industry,Ocean exploitation,Geothermal engineering,Concrete is also an important material。The concrete pump is composed of a pump body and a conveying pipe。It is a kind of machine that uses pressure to transport concrete continuously along the pipeline, mainly used in house construction, bridge and tunnel construction。At present, it is mainly divided into gate valve concrete conveying pump and S-valve concrete conveying pump。The other is to install the pump body on the chassis of the car, and then equipped with a telescopic or flexed fabric rod, and composed of a pump truck。

Concrete mixing station is widely used in infrastructure construction, many users of the understanding of concrete mixing station is only limited to how to use, for the quality of concrete mixing station is good or bad, and not very understanding, let alone to check the quality of the station bought。The main components of the concrete mixing station are also a few, so as long as these major components do not have quality problems, then the concrete mixing station does not have too much quality problems。1.If the mixer is a self-falling mixing drum, the radial runout of the discharge ring does not exceed 1% of the diameter of the feed port, but also check the quality of the steel bar of the vibrating screen mesh on the mixer and the reasonable size of the screen and screen hole and check the installation accuracy of the screen;2.The operation of the transmission system should be flexible, without abnormal sound;3.tangibleCylinder batcherproducerBelt conveyor, bucket elevator and cantilever shovel transmission should be smooth, the operation should be flexible, the brake can be high, no abnormal noise, no card chain;4.The inspection of the measurement system is also very important, to check the sensitivity and accuracy of the measurement system;5.Reduce the lifting temperature of the machine should also pay attention to reach the temperature of the qualified book;6.Metering hopper in and out of the material should be smooth, no accumulation, overflow and other phenomena;7.tangibleCylinder batcherproducerSafety valve can not appear leakage phenomenon;8.The quality of cement tank is qualified;9.The matching line installation should be reasonable and the installation of equipment should be correct。

Winter mixing plant how to maintain the winter season temperature is very low, the construction conditions and the environment are unfavorable, is the frequent season of engineering quality accidents, especially the concrete project。Mixing station as a necessity for engineering equipment,德阳tangibleCylinder batcherHow to do winter maintenance work?1, the winter temperature is too low, mixing station does not produce, please exclude residual water in time to prevent freezing and freezing water pump。At the same time, pay attention to the water in the water additive pipeline to prevent the water from freezing in the pipeline, affecting normal production。2. It is strictly prohibited to wash the floor with high pressure water。Because high pressure water is not easy to control, it is easy to splash onto the motor, electric control box, wire trough and other equipment。Although all kinds of equipment generally have waterproof measures, a large amount of water with pressure will still cause motor short circuit, electric control box water and other conditions。A long period of soaking water in a cable trough may cause interface leakage and cable string faults, which may cause equipment damage or even safety accidents。3, winter is coming, should be timely remove the mixing station drum next to the sand。Because the sand is wet, if there is too much accumulation, the sand and stone will freeze and cut the drum like a grinder, which is easy to cut off or damage the drum。4, should always check whether the roller is not running the hair clip phenomenon, if the roller does not run, will cause the belt on the roller dry friction, light damage to the roller, heavy damage to the belt。5, mixing station in the non-production should be timely air compressor and air road in the residual gas exclusion, because the residual gas is easy to solidify into water, cold easy to freeze,tangibleCylinder batcherproducerMay cause the next production of the gas path is not smooth or the valve and cylinder operation is not good。

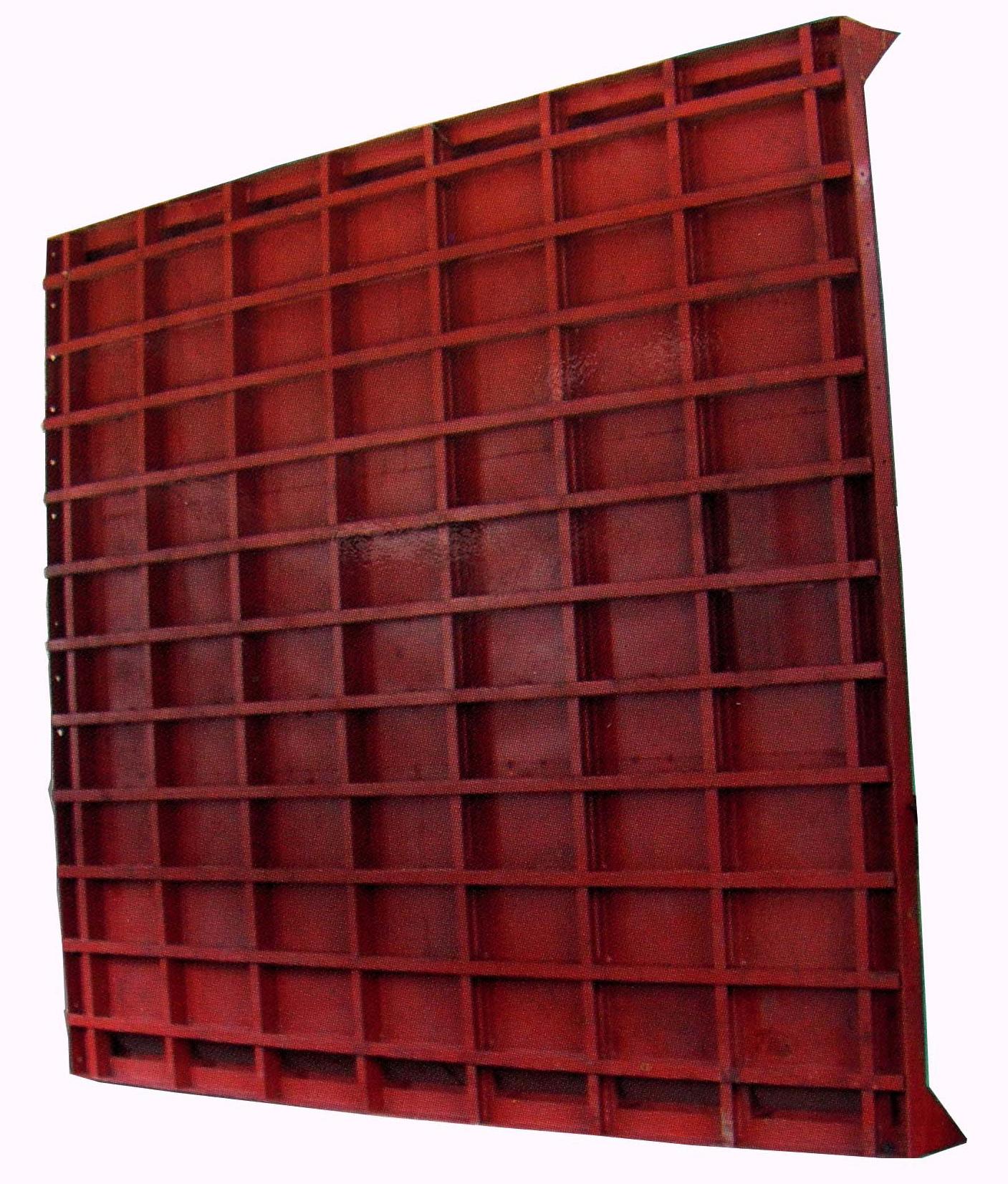

德阳tangibleCylinder batcherWhen loading, the mixture to be stirred is installed in the hopper, the feeding system is started, the wire rope pulls the hopper to climb up, when climbing to a certain height, the hopper enters the loading rack, the hopper door automatically opens, and the material is unloaded into the mixing cylinder through the funnel。JS750 mixer mixing system is composed of motor, pulley, reducer, gear, mixing device, mixing cylinder and so on。The main motor is connected to the two-stage gear reducer through the belt, and finally through the two pairs of open gears respectively drive the two horizontal mixing shaft to rotate towards the same speed。The electrical control system needs to control the main drive motor of the JS750 mixer, the motor of the water supply system, the motor of feeding, unloading, etc。All electrical control elements are located in the distribution box。The electrical components in the distribution box are installed on an iron plate, which is safe and reliable, easy to operate and maintain。The discharge system is at the bottom of the mixer, and the discharge is carried out by a manual push rod。According to customer requirements, we can produce mixers in the form of electric push rod discharge。The connection between the discharge door and the mixing cylinder shall be sealed with a sealing plate.Cylinder batcherproducerThe position of the seal plate can be adjusted to ensure the purpose of sealing。